IC, SoC를 및 FPGA 디자이너를 위한 디버깅 도구

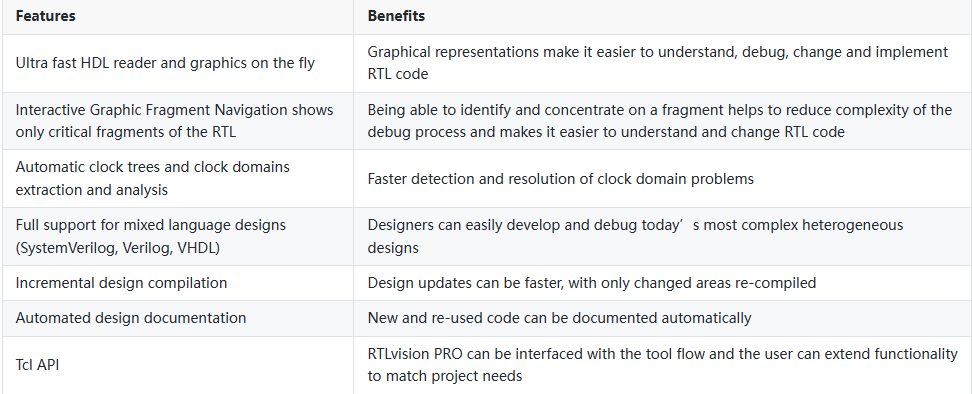

RTLvision PRO

RTL viewer and debugger for SystemVerilog and VHDL SoCs & IP

RTLvision® PRO simplifies the visualization of large RTL designs, including third party IP and reused blocks. Using Concept’s award winning visualization technology, the tool provides the unique and effective graphical rendering of RTL code structures, allowing engineers to quickly appreciate design functionality. Supporting SystemVerilog, VHDL and Verilog, RTLvision PRO comes complete with a range of debug views such as a powerful waveform display, an interactive cone of influence window, and other displays for a complete, 360° picture of the device.

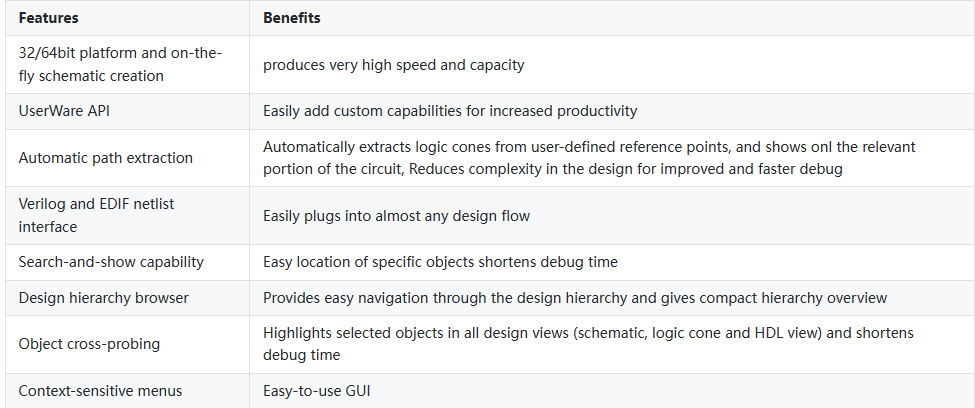

GateVision® PRO is the third generation of graphical, gate-level netlist analyzers and viewers from Concept Engineering. Completely rewritten to run on modern 64bit platforms to handle the largest designs and SoCs, GateVision PRO provides a range of powerful debug and comprehension capabilities. These include intuitive design navigation, netlist viewing, waveform viewing, logic cone extraction, interactive logic cone viewing for netlist debugging and design documentation.

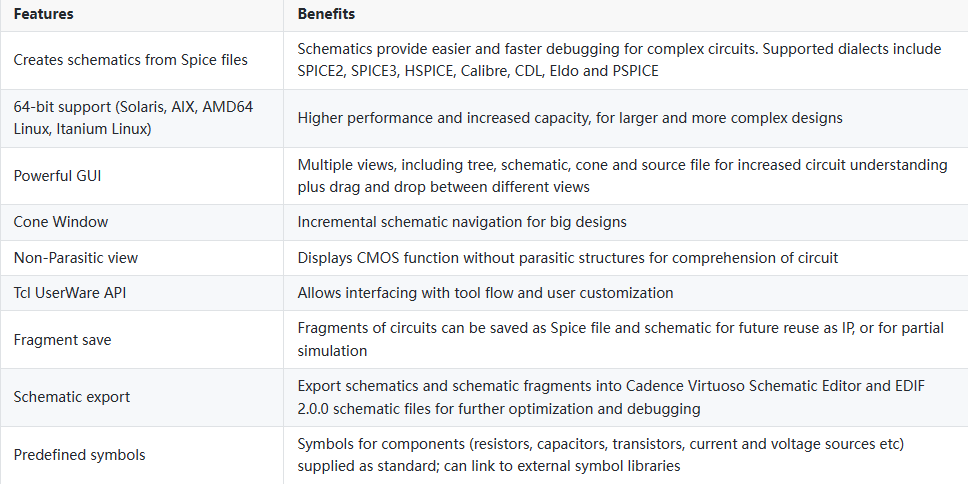

SPICEVISION pro

High Capacity Transistor-Level Debugger and Viewer

piceVision® PRO takes SPICE netlists and models and generates clean, easy-to-read transistor-level schematics, circuit fragments, and design documentation to speed up circuit design, debug, and optimization at the transistor-level.

SPICE circuits and models are the common currency of the EDA world. They are generated by many EDA tools and provide a description of the circuit at the lowest component abstraction level, the transistors, capacitors, resistors and even the interconnect that make up an IC or IP components. But for all but the most of trivial designs, SPICE files are very difficult to read and understand. SpiceVision PRO automatically generates visual circuit schematics, accelerates debug and helps to solve design problems in Digital Circuits, Mixed-Signal ASICs, Analog Circuits, Printed Circuit Boards and MEMS.

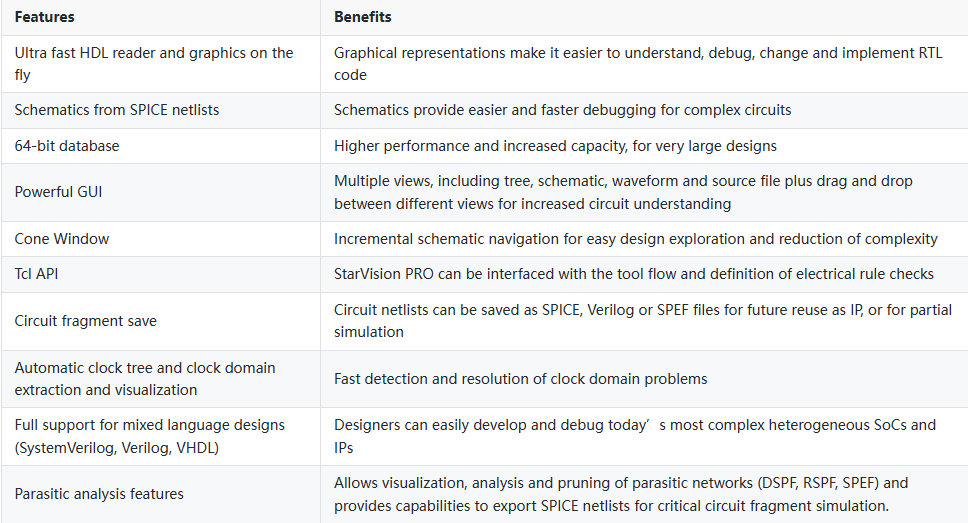

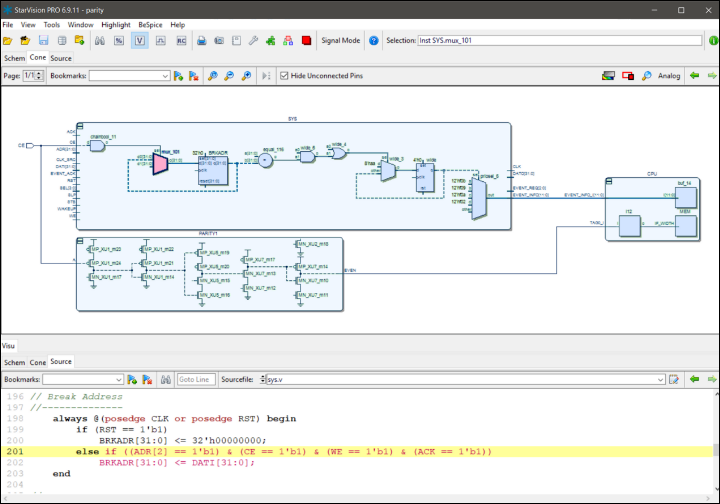

STARVISION pro

SoC, Multi-mode Debug for Transistor, RTL, and System-Level Designs

StarVision® PRO represents the state-of-the-art in debug solutions for advanced electronic SoCs. The incorporation of Concept’s leading visualization and detection technology enables rapid cause-effect analysis for efficient functional analysis. This advanced and unique mixed-mode debug platform seamlessly combines SPICE and transistor analysis from our market leading SpiceVision PRO tool with digital RTL and gates from our advanced RTLvision PRO tool. It is fully customizable and incorporates many advanced features not available in other debug solutions, to handle the most complex of SoC platforms.

EDA 툴 개발자를 위한 소프트웨어 구성 요소 (도식 세대)

NIview

Concept Engineering’s Nlview® engine provides automatic generation of schematic diagrams for different levels of electronic circuits, including gate-level, RTL and block-level. Optional engines are available for the system-level (S-engine), for the transistor-level (T-engine), and for automotive and aerospace applications (E-engine). The schematic layout can be modified and controlled by human intervention and always optimized by algorithms. A fine granularity of user preferences can be mixed with machine computed “beauty” to get the best human readable diagrams. Interactive circuit exploration is supported by incremental schematic generation technology. Nlview provides a set of APIs and interfaces with a certain GUI environment.

Nlview 소프트웨어 구성 요소에 대한 옵션

T-엔진

In response to demand from the electronic design automation (EDA) and the semiconductor industries, Concept Engineering has developed completely new algorithms that generate easy-to-read transistor-level schematics. T-engine recognizes common device-level circuit patterns, and can detect and analyze serial/parallel circuit paths. It also can perform current flow analysis (i.e., power-to-ground flow) and logic flow analysis including both left-to-right flow and reverse-flow detection for feedback.

S-엔진

he complexity of modern automotive and aerospace electronic systems has exploded, creating a major problem for vehicle service operations. Technicians and mechanics must wade through hundreds of pages of incomprehensible, sometimes out-of-date, static, documentation, attempting to apply complex schematics to unfamiliar repair scenarios. This is a significant challenge for automotive and aerospace manufacturers where the effective maintenance of their products is a key differentiator. The initial documentation production, applying document revisions, and providing the flexibility to handle vehicle variations all require a considerable investment.